In 1967 in Winona, MN, a man named Bob opened a 1000-square-foot shop selling nuts and bolts. Nothing about this little shop screamed “future Fortune 500 company.” But Bob wasn’t just building a fastener supply business – he was about to disrupt conventional business models with some good old Midwestern common sense. Bob trusted his people as a foundation for his business. More than 50 years later, that foundation still holds. Bob’s business is Fastenal, and today Fastenal employs 23,000 employees and did $7b in annual revenue.

Why should we in healthcare pay attention to a guy who sold screws in the Midwest?

Because Bob Kierlin understood something fundamental: that good jobs, autonomy, and operational excellence aren’t nice-to-haves, but building blocks for a good business. “Fastenal has no unique product and no unique process,” Bob once said, “… but it has some ideas about people that are at least uncommon, if not unique.”

Industrial Vending Machines

One of Fastenal’s most innovative moves didn’t come from the boardroom, but from the field.

In the 2000s, Fastenal began rolling out industrial vending machines—those big blue boxes filled not with chips and soda, but with drill bits, gloves, and safety goggles. The idea was simple: place supplies right where they’re needed, and let workers access them without jumping through hoops or filling out forms.

But the real genius wasn’t just the machine — it was the feedback loop.

Store managers and branch employees shaped how these machines were stocked, tracked, and integrated. Workers knew what their customers needed – features like inventory tracking, theft prevention, and integration into supply chains.

So, Fastenal listened to the folks on the front lines. Instead of a credit card reader, they developed machines that required employees to input identification codes and job numbers before dispensing items. They iterated, improved, and turned an uncommonly clever idea into a core part of their business.

It wasn’t about top-down innovation. It was about bottom-up insight.

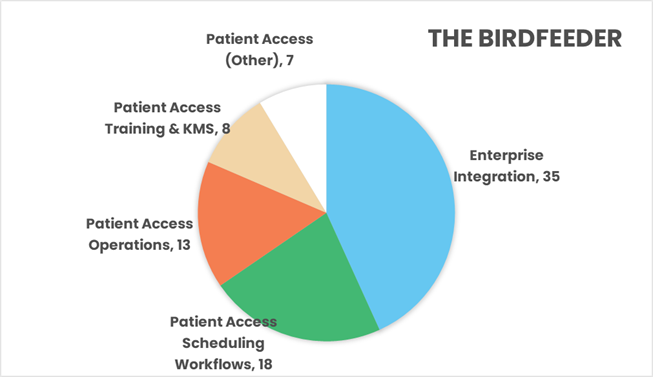

At Hummingbird, bottom-up insights are how we build. By rejecting traditional healthcare bureaucracy, outdated software, and redundant workflows (1981 really does want its fax machine back), we create environments where frontline team members have a say in the innovations and optimizations we prioritize – right alongside executives and managers. Our Peakon employee engagement tool has generated thousands of constructive comments. The “Birdfeeder” (our digital suggestions box) has generated 75 specific ideas in the last two months, many of which are now in production.

Nobody can spot waste better than those on the front lines. Our best ideas come from individual team members spotting patterns in their calls, schedulers hacking together shortcuts, and supervisors figuring out how to keep morale high during the 4 PM rush.

Like Fastenal’s vending machines, our best ideas come from listening. From building with, not just for, the people doing the hard work. And it turns out when you listen to people and act on their feedback, they’re also more likely to stay and do great work. In fact, we consider “listening” to be a core tenant of how we create Good Jobs at Hummingbird.

Bob Kierlin grew up just 90 minutes south of my hometown outside the Twin Cities. He passed away this February at the age of 85. His “extreme” principles built a $40B industrial legacy.

Now, those principles are helping us build a better, more human model for healthcare access.